After extensive model tests and tests under operating conditions, SORG® has developed a patented CONTI-DRAIN® system for forehearths, specifically to remove contaminated glass, especially zircon cords (cat scratches).

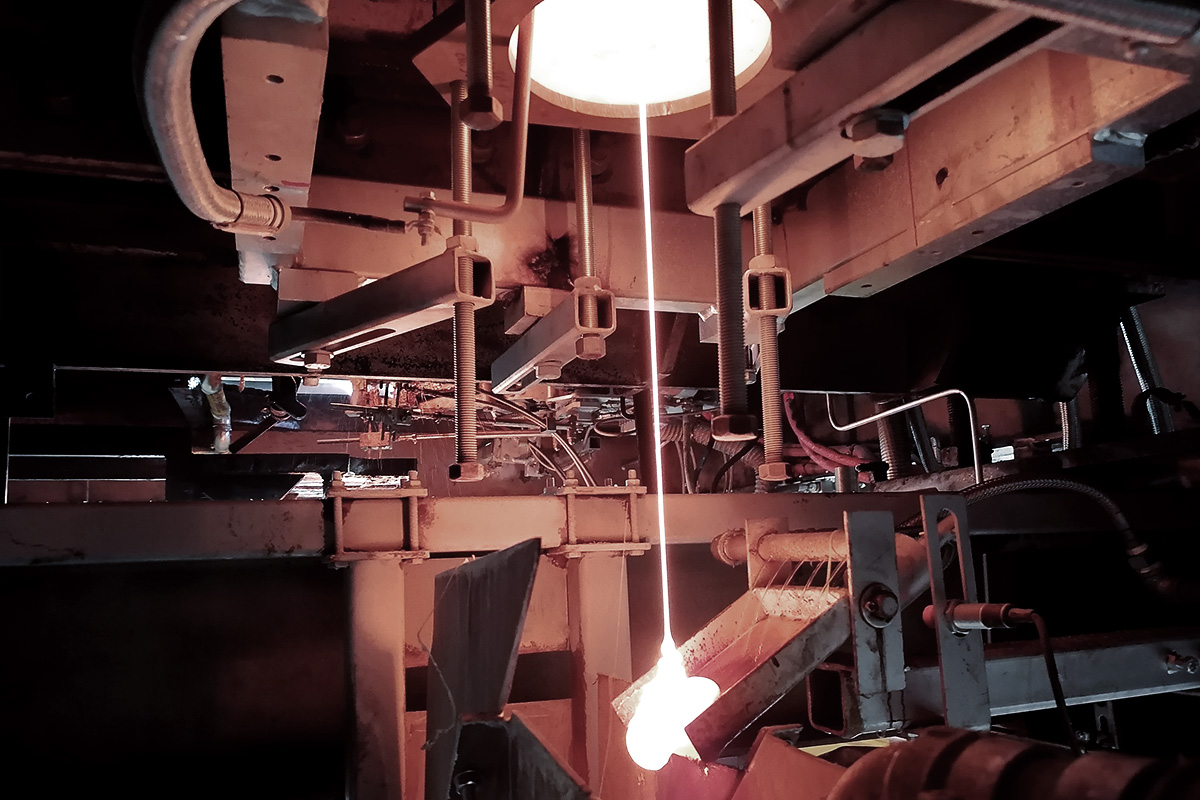

The drain itself consists of a high-temperature resistant steel plate that acts as an outlet nozzle. The equipment is placed up against the underside of the outlet hole in the channel block.

A simple ceramic holder assembly is used to keep the metal plate in position and provide electrical insulation. A thermocouple measures the temperature of the outlet nozzle. The electrical heating system comprises a small double-wound transformer with a thyristor unit to provide stepless voltage variation. A temperature controller is used to maintain a constant temperature at the outlet nozzle, which results in a continuous flow of the glass.

Adjustment of this temperature gives a change in the amount of glass being drained.

On a new installation or repair, the drain block can be installed without the drain equipment. It is possible to install drain equipment and activate the system later if it becomes necessary.

Under some circumstances, it is possible to install a forehearth CONTI-DRAIN® on an existing forehearth with no special channel block by drilling the required profile from outside of the forehearth.

The standard CONTI-DRAIN® system utilises a molybdenum counter electrode in the glass bath. In the case of highly oxidised soda-lime flint glasses, this can lead to blister formation and, although most of these will be removed by the drain, a few may be found in the production. We have developed a version of the forehearth CONTI-DRAIN® that does not need a counter electrode for these applications.

Experience has shown that the forehearth CONTI-DRAIN® is capable of reducing or eliminating visible zircon cord in the production.

ADVANTAGES

- The only system that has consistently reduced or eliminated zircon cord